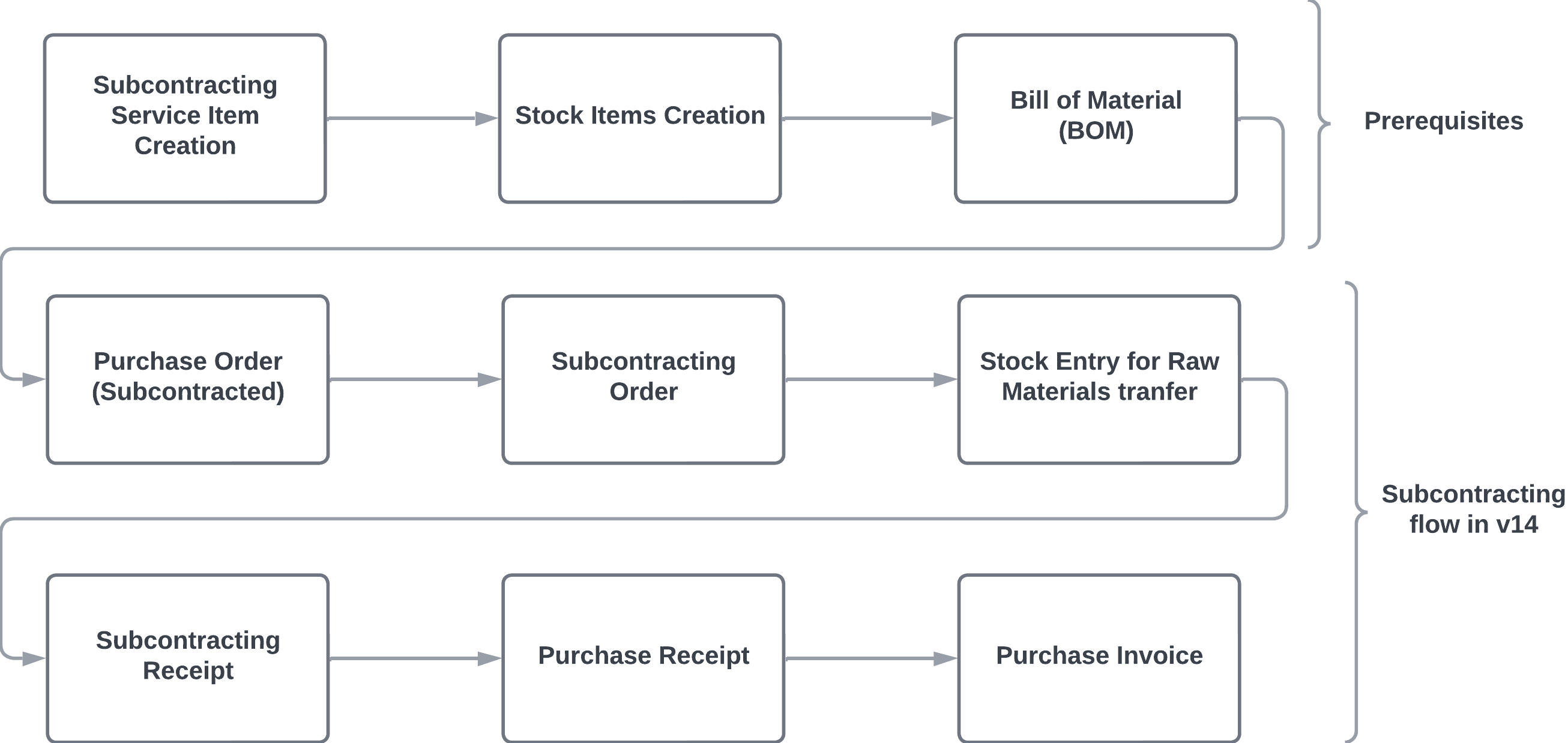

practical mapping of what manufacturers expect → ERPNext modules & DocTypes.

By Annor Amapolley on January 15, 2026

ExpertBelow is a clean, practical mapping of what manufacturers expect → ERPNext modules & DocTypes.

This is written the way you would explain it to a factory owner or operations manager, not as technical documentation.

1️⃣ Product Structure & BOM Control

Expectation

“I want to define my products properly and know exactly what goes into each one.”

ERPNext Module

- Manufacturing

- Stock

Key DocTypes

- Item

- Item Group

- Bill of Materials (BOM)

- BOM Operation

- Workstation

What ERPNext does

- Defines finished goods, sub-assemblies, and raw materials

- Calculates standard cost per product

- Supports multi-level BOMs

2️⃣ Production Costing (Material, Labor & Overheads)

Expectation

“Tell me the real cost of producing one unit.”

ERPNext Module

- Manufacturing

- Accounts

Key DocTypes

- BOM

- Workstation

- Operation

- Work Order

- Stock Entry (Manufacture)

What ERPNext does

- Rolls up:

- Raw material cost

- Operation cost (per hour)

- Posts absorbed cost into inventory

- Updates valuation automatically

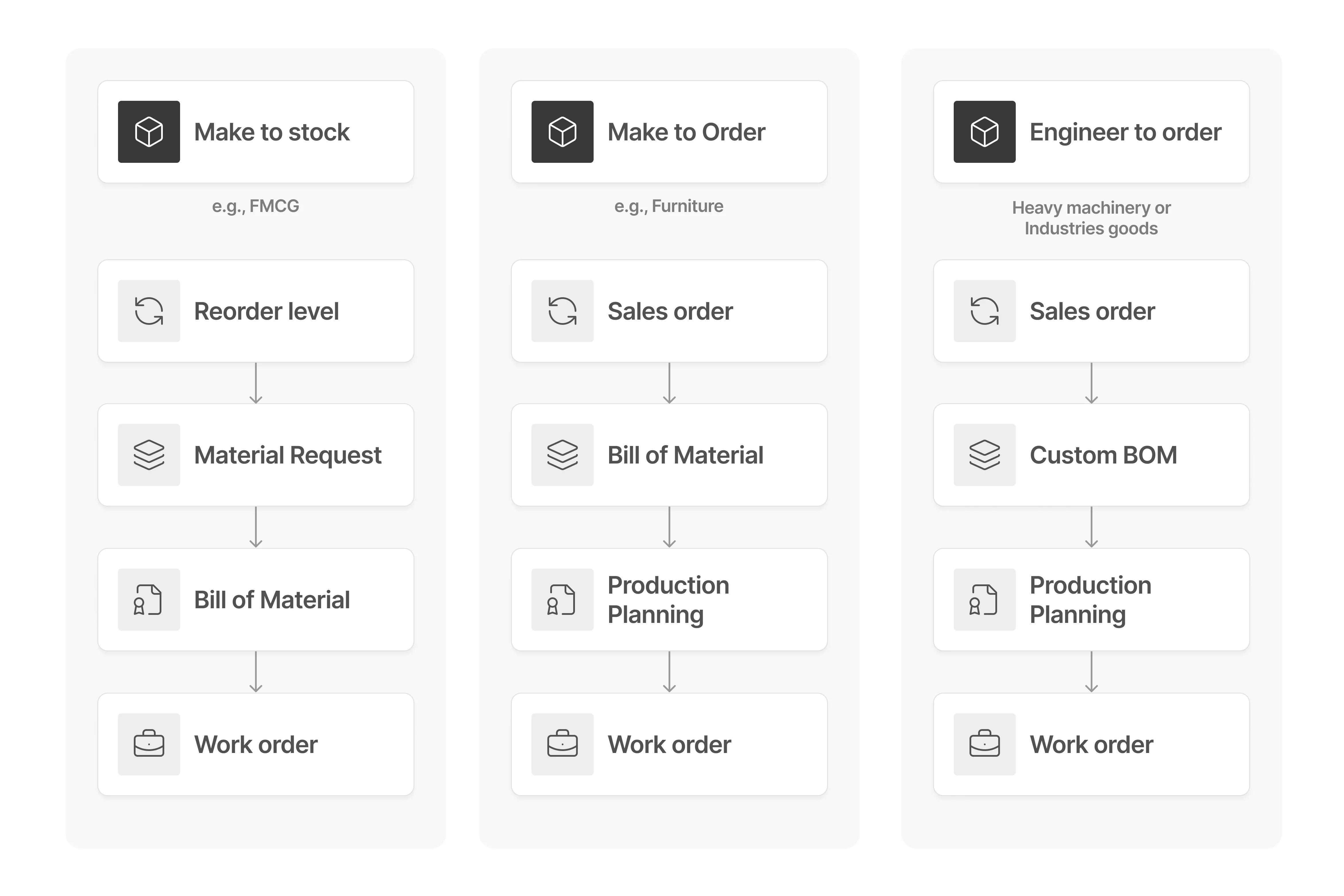

3️⃣ Production Planning & Scheduling

Expectation

“Tell me what to produce, when, and if I have materials.”

ERPNext Module

- Manufacturing

- Stock

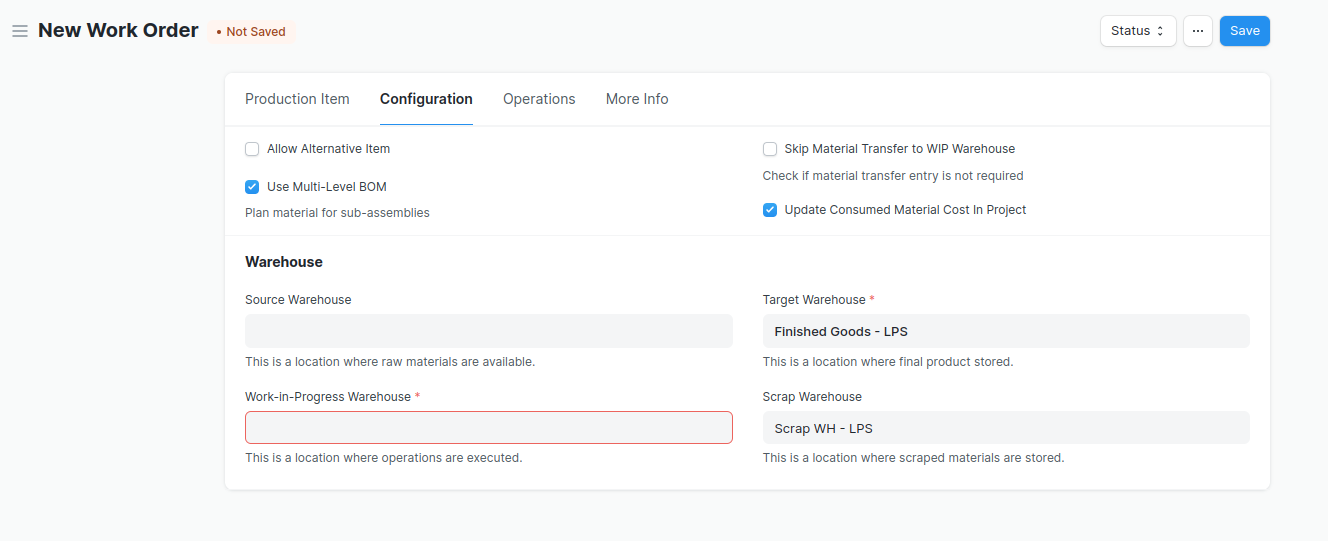

Key DocTypes

- Production Plan

- Material Request

- Work Order

What ERPNext does

- Converts demand → production plan

- Checks material availability

- Generates work orders and purchase requests

4️⃣ Raw Material, WIP & Finished Goods Control

Expectation

“I want to see where my materials are at every stage.”

ERPNext Module

- Stock

Key DocTypes

- Warehouse

- Stock Entry

- Stock Ledger Entry

- Bin

What ERPNext does

- Tracks:

- Raw material stores

- Work-In-Progress (WIP)

- Finished goods

- Provides real-time stock balances

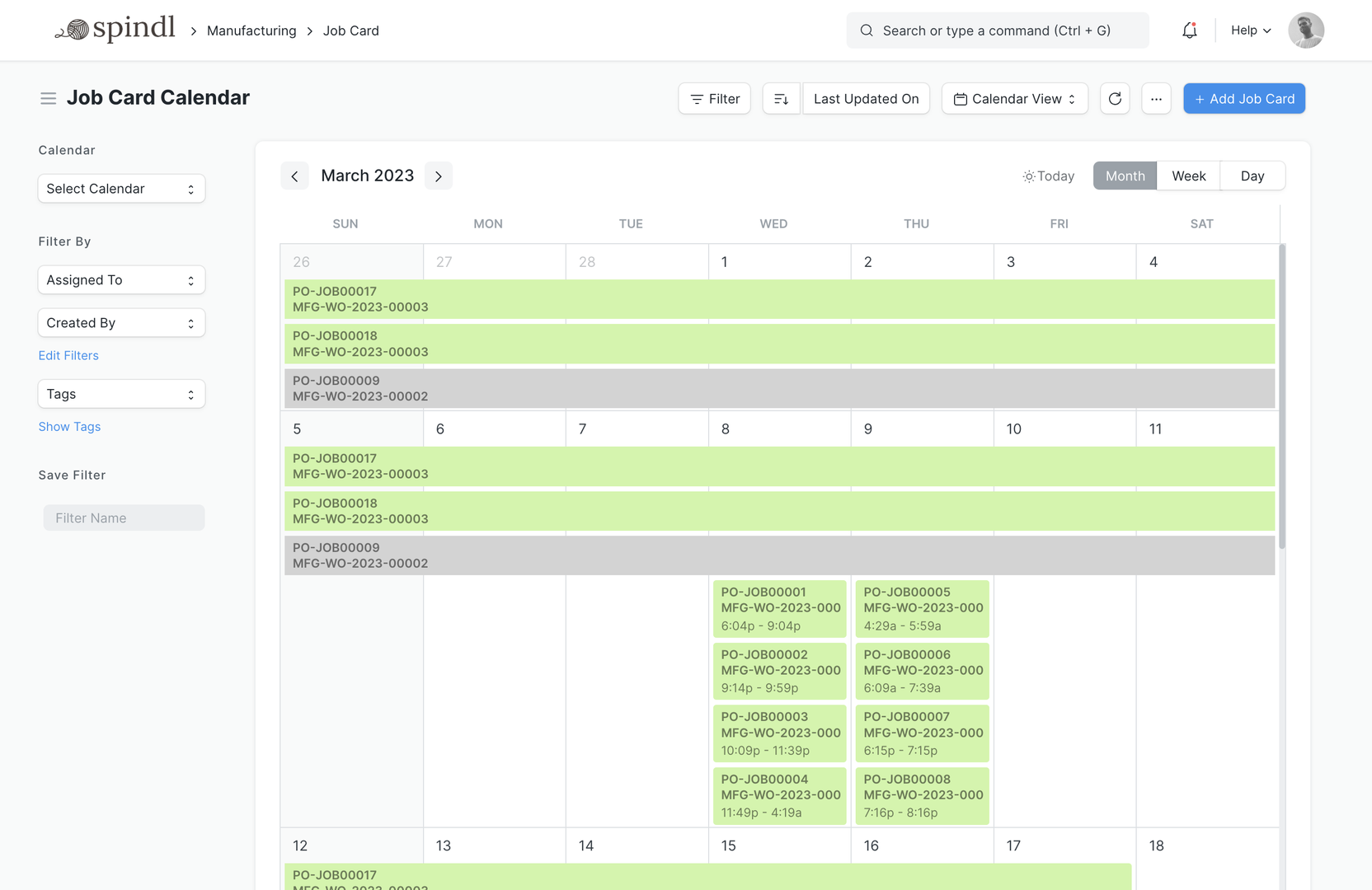

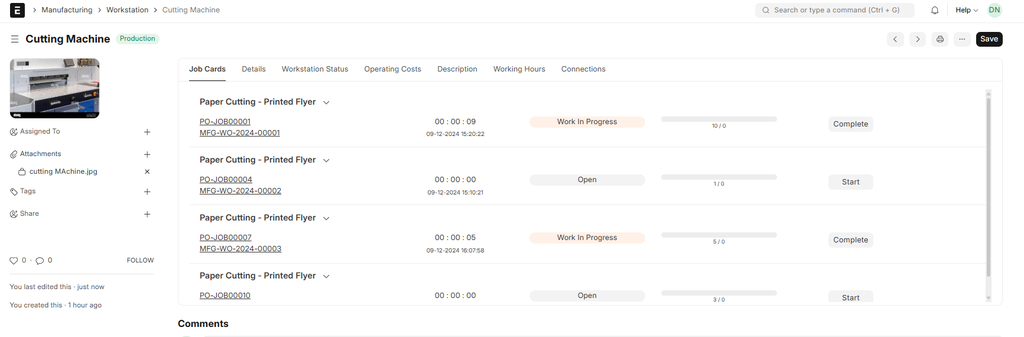

5️⃣ Shop Floor & Operations Tracking

Expectation

“I want to know who worked on what, for how long.”

ERPNext Module

- Manufacturing

Key DocTypes

- Operation

- Workstation

- Job Card

What ERPNext does

- Captures:

- Operation start/stop time

- Actual hours vs planned hours

- Measures efficiency and bottlenecks

6️⃣ Quality Control & Traceability

Expectation

“I must control quality and trace every batch.”

ERPNext Module

- Quality

- Stock

- Manufacturing

Key DocTypes

- Quality Inspection

- Quality Inspection Template

- Batch

- Serial No

What ERPNext does

- Enforces inspections

- Tracks expiry dates

- Enables batch-level traceability

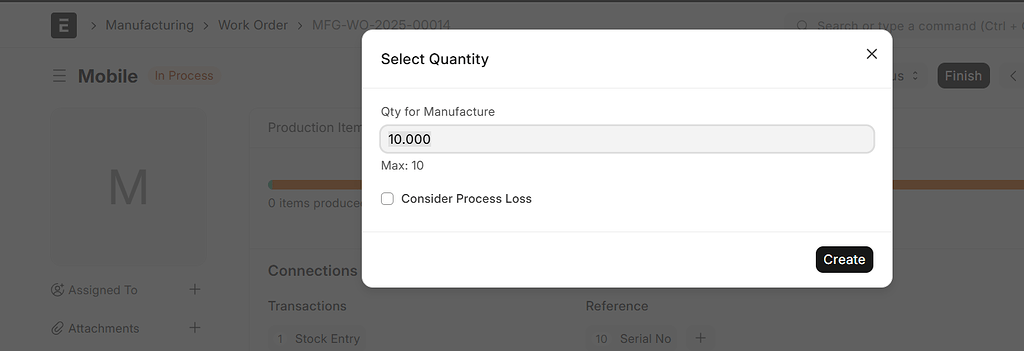

7️⃣ Scrap, Process Loss & Yield

Expectation

“Show me waste, losses, and yield differences.”

ERPNext Module

- Manufacturing

- Stock

Key DocTypes

- BOM (Scrap Item / Process Loss)

- Stock Entry

- Work Order

What ERPNext does

- Records scrap during production

- Reflects loss in costing

- Enables yield analysis

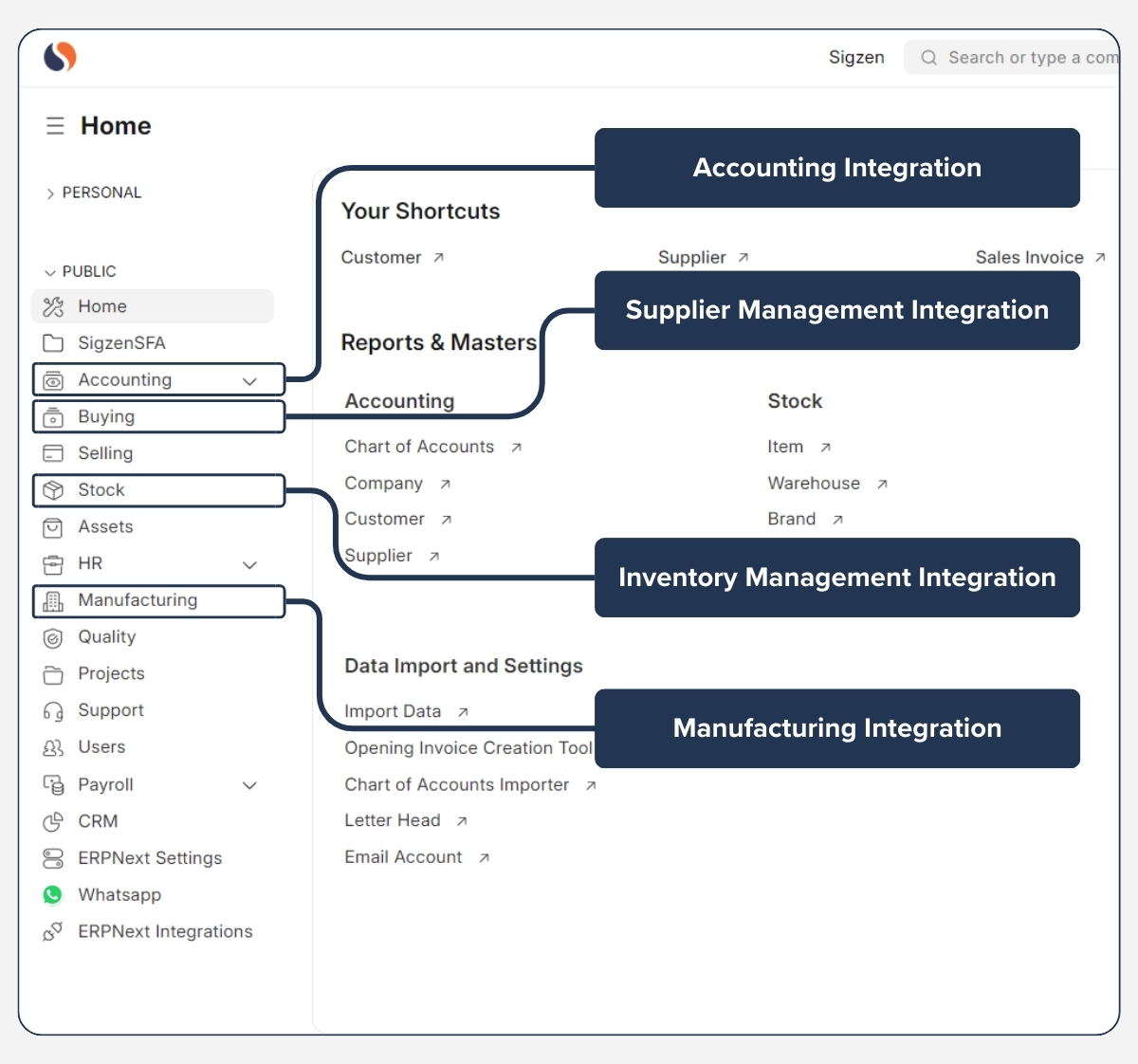

8️⃣ Financial Posting & COGS Integration

Expectation

“Production must automatically hit my accounts.”

ERPNext Module

- Accounts

- Stock

- Manufacturing

Key DocTypes

- Stock Entry

- GL Entry

- Account

- Cost Center

What ERPNext does

- Auto-posts:

- Inventory value

- Production cost

- Cost of Goods Sold (COGS)

- Eliminates manual journals

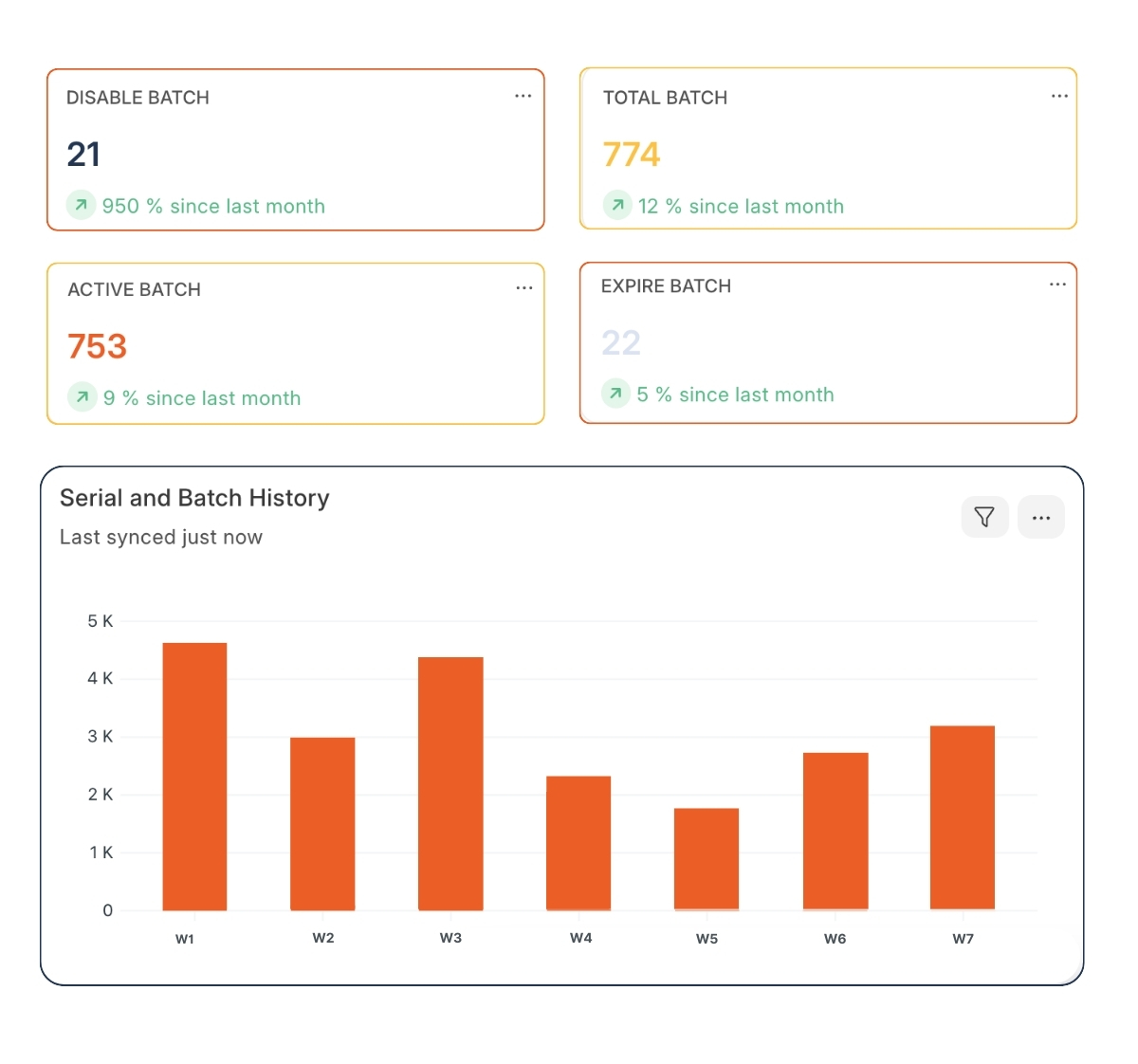

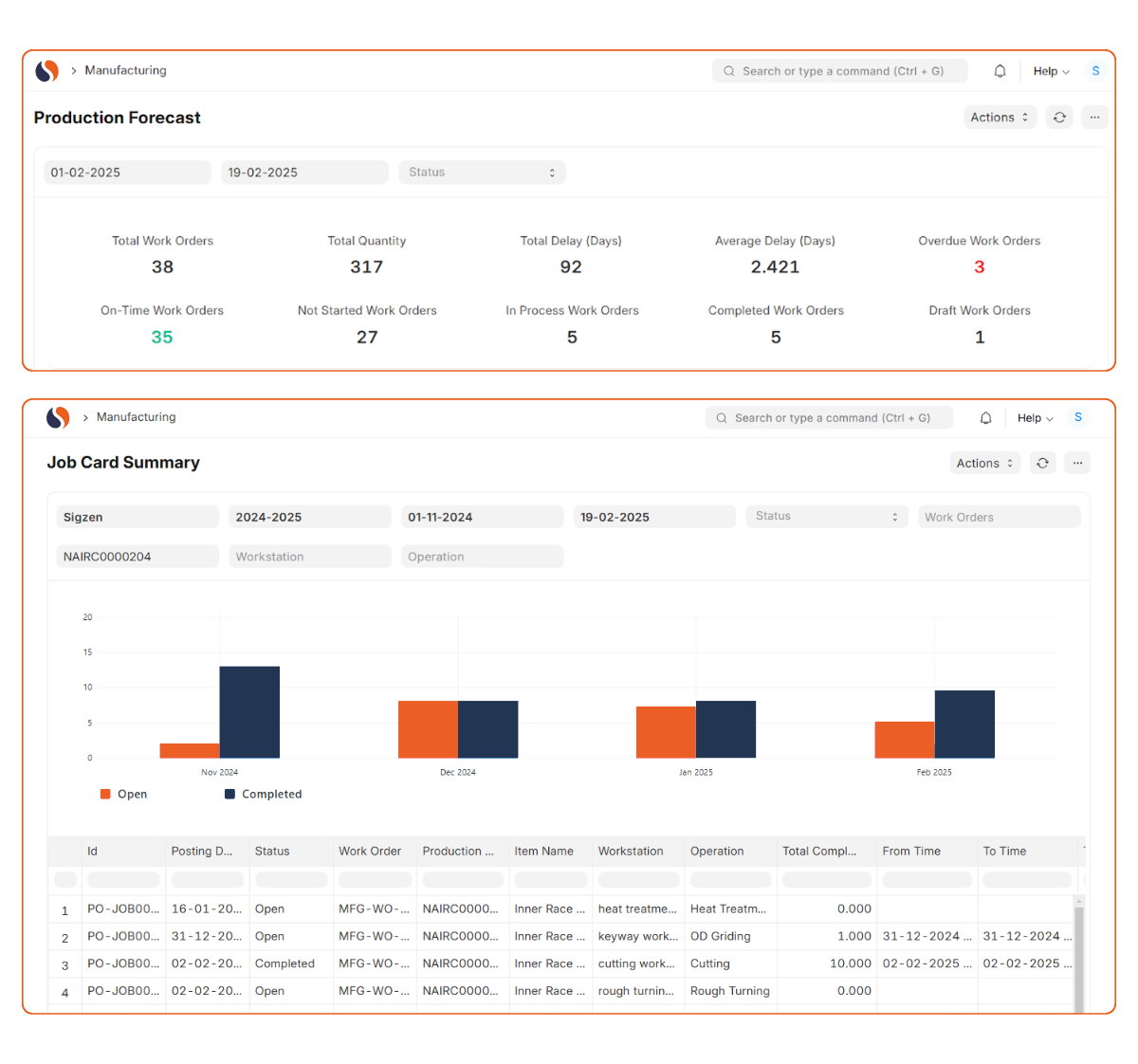

9️⃣ Reporting & Management Dashboards

Expectation

“Give me reports that help me make decisions.”

ERPNext Module

- Manufacturing

- Stock

- Accounts

Key DocTypes / Tools

- Query Report

- Dashboard

- Number Card

- Report Builder

What ERPNext does

- Shows:

- Cost variance

- Efficiency

- Profitability by product

- Supports executive dashboards

🔟 Scaling Across Plants & Processes

Expectation

“This system should grow with my factory.”

ERPNext Module

- All Core Modules

Key DocTypes

- Company

- Warehouse

- Cost Center

- Workstation

What ERPNext does

- Supports:

- Multiple factories

- Multiple warehouses

- Centralized reporting

🧠 Simple Mental Model (Use this with Clients)

Sales Order → Production Plan → Work Order → Job Card → Stock Entry → Financials → Reports

This is the manufacturing heartbeat in ERPNext.

🎯 Consultant Tip (Very Important)

In demos, don’t start with BOM.

Start with:

“This is how the system shows you your true cost per unit and where money is leaking.”

That instantly connects with owners and CFOs.

More articles on Erpnext