Expectations of Manufacturers on ERP Systems

By Annor Amapolley on January 15, 2026

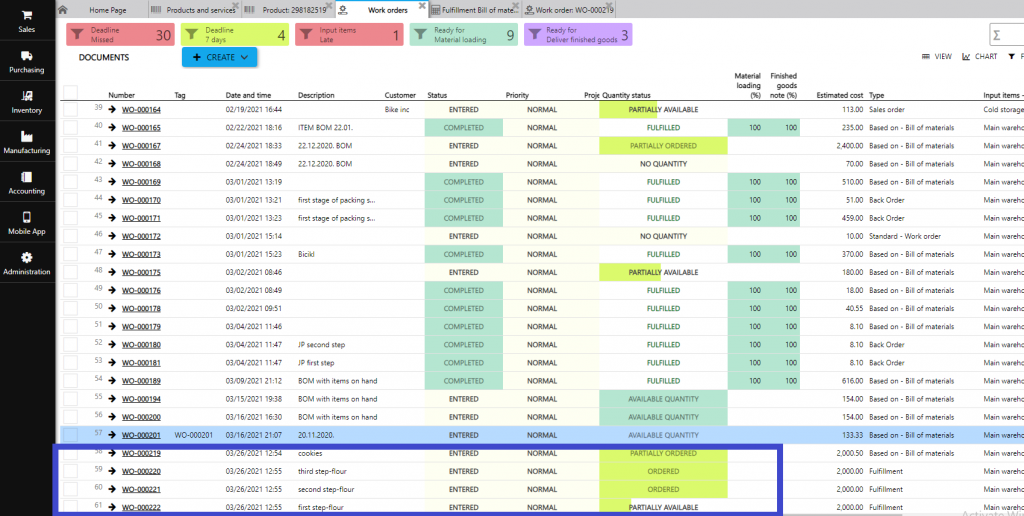

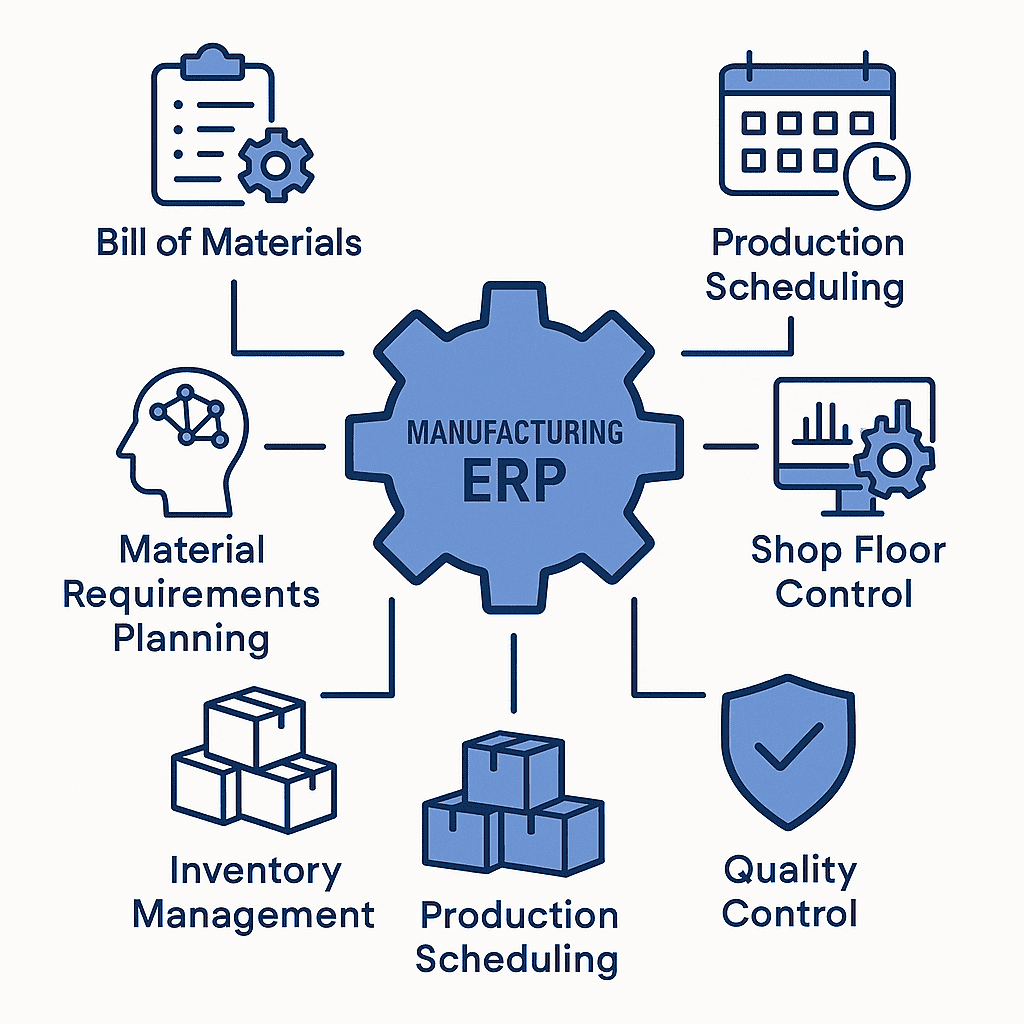

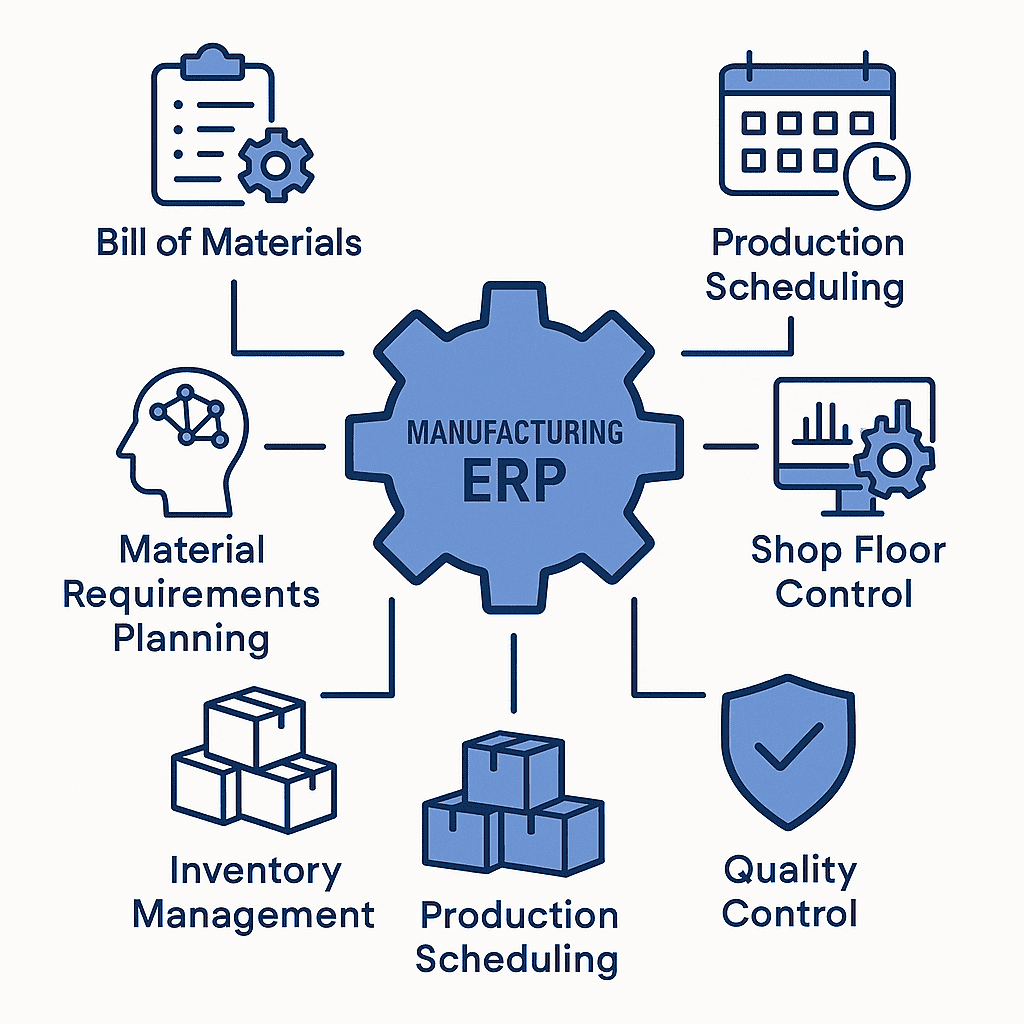

ExpertWhen companies adopt a manufacturing module in ERPNext (or any serious manufacturing software), they are not just “recording production.” They are usually trying to control cost, visibility, planning, and execution across the entire factory lifecycle.

Below is a clear, practical breakdown of what manufacturers actually expect the system to do for them.

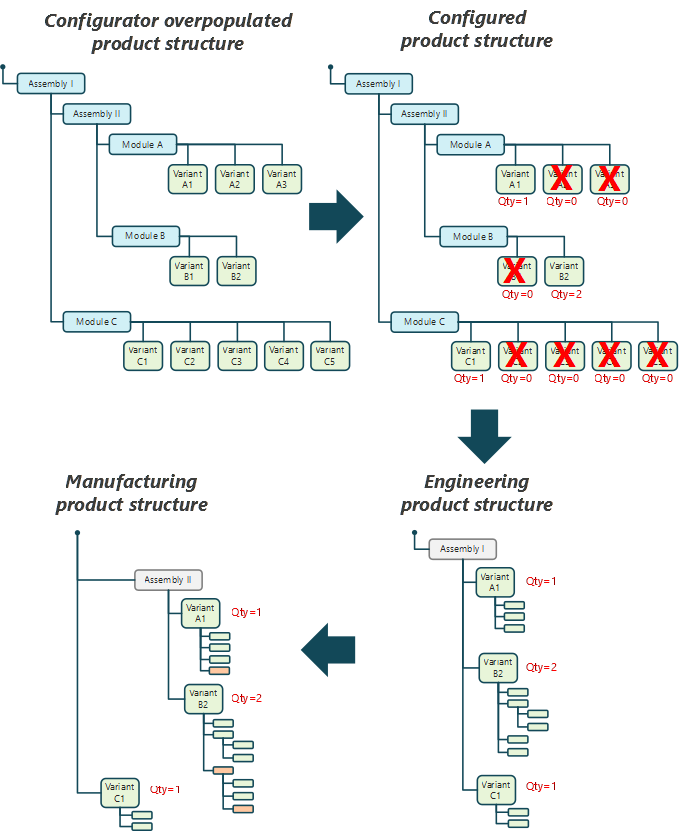

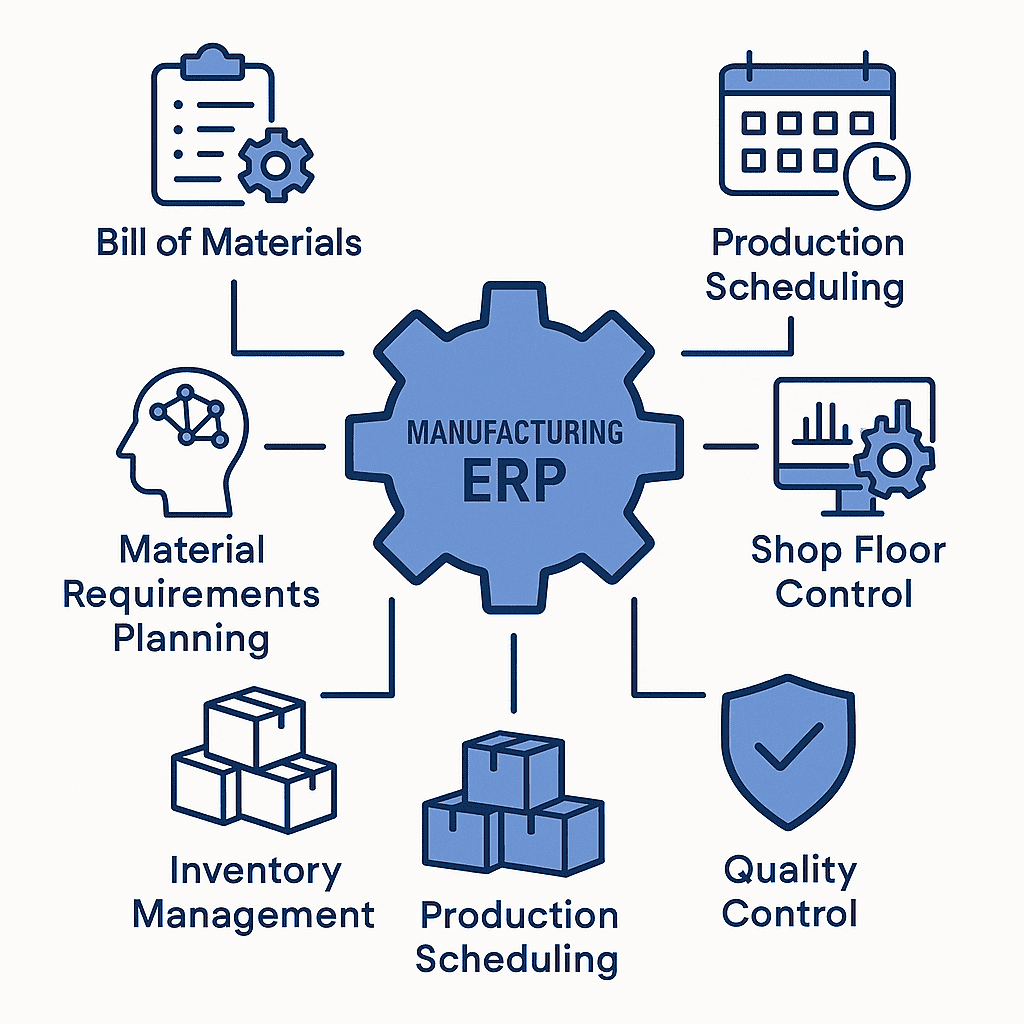

1️⃣ Product & Bill of Materials (BOM) Control

What they want

- Define finished goods, sub-assemblies, and raw materials

- Standardize recipes / formulations / components

- Control versions of BOMs (old vs new design)

- Know exact quantity & cost of each component

Why it matters

- Eliminates guesswork

- Prevents material wastage

- Forms the foundation for accurate costing

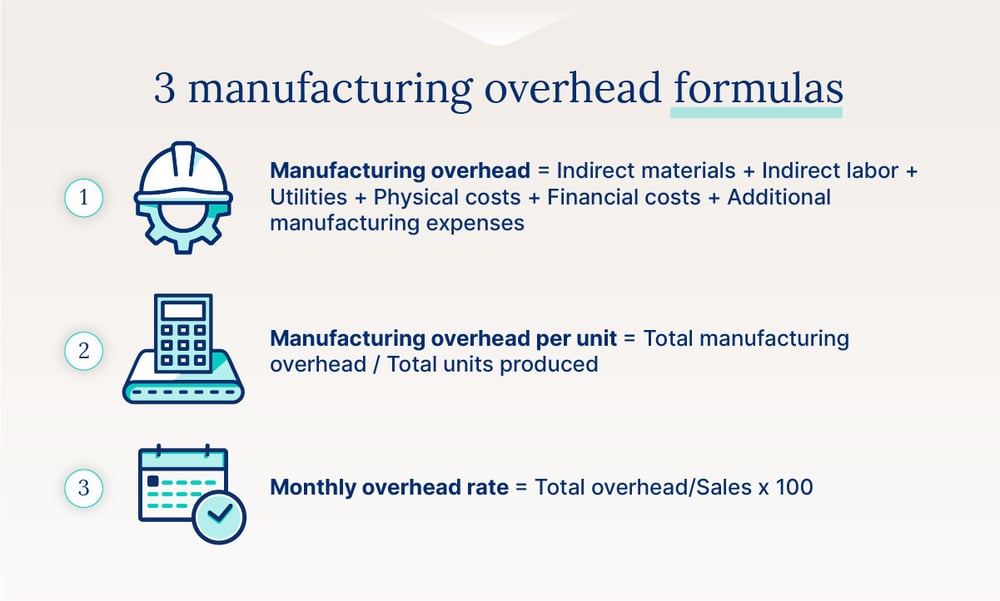

2️⃣ Accurate Production Costing (Very Important)

What they want

- Know true cost per unit, including:

- Raw materials

- Labor

- Machine/operation costs

- Overheads (power, fuel, depreciation)

- Compare planned vs actual cost

- Detect cost leakage early

Typical questions owners ask

- “Why is this product no longer profitable?”

- “Which step is driving up my cost?”

3️⃣ Production Planning & Scheduling

What they want

- Plan production based on:

- Sales orders

- Forecasts

- Stock levels

- Know:

- What to produce

- When to produce

- How much to produce

Business value

- Avoid stockouts

- Avoid overproduction

- Meet delivery deadlines confidently

4️⃣ Inventory & Raw Material Control

What they want

- Auto-reserve raw materials for production

- Track:

- Raw Materials

- Work-In-Progress (WIP)

- Finished Goods

- See real-time stock balances

Outcome

- No sudden “material shortage” during production

- Better purchasing decisions

- Reduced dead stock

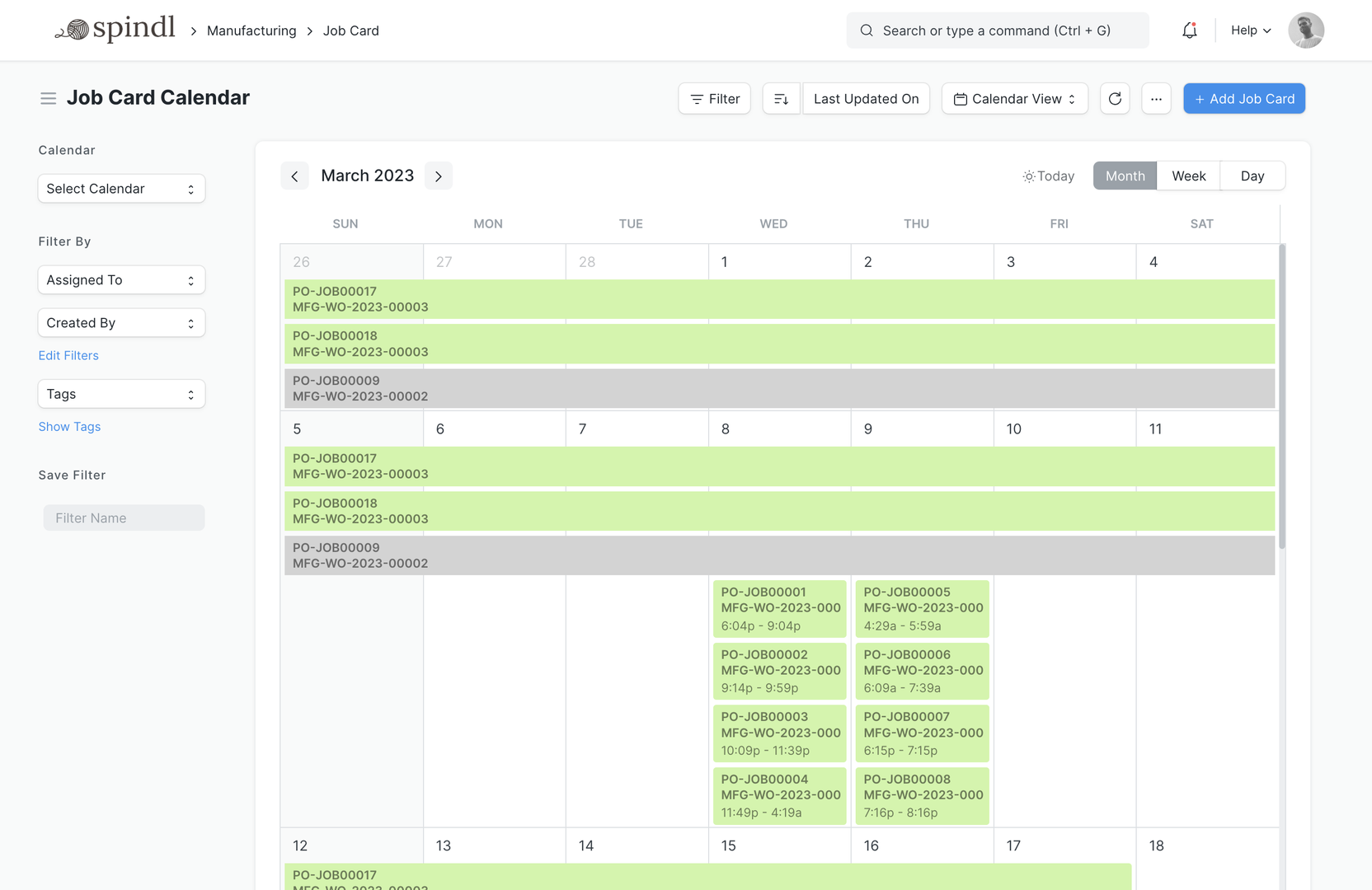

5️⃣ Shop Floor & Operations Tracking

![]()

What they want

- Track:

- Each operation (cutting, mixing, assembly, packaging)

- Time spent per operation

- Machine usage

- Measure operator productivity

Why it matters

- Identifies production bottlenecks

- Improves efficiency

- Supports incentive or performance systems

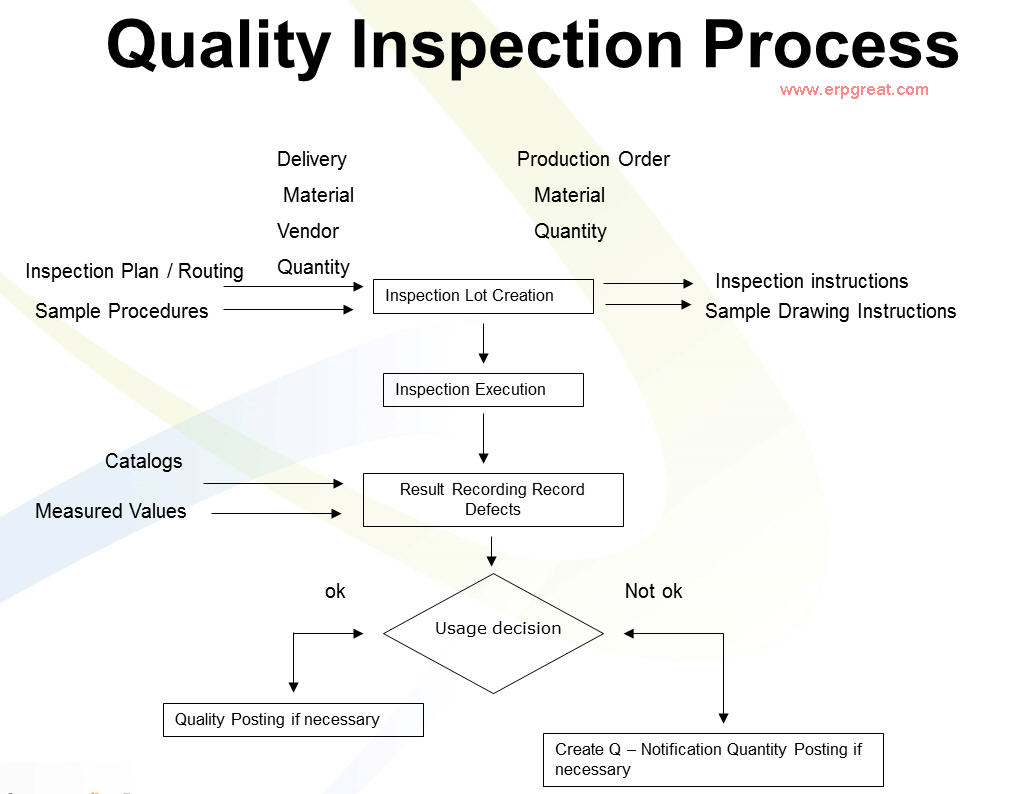

6️⃣ Quality Control & Compliance

What they want

- Inspect raw materials and finished goods

- Enforce quality checkpoints

- Track batches & expiry dates

- Support audits (especially food, pharma, FMCG)

Result

- Fewer customer complaints

- Traceability during recalls

- Regulatory compliance

7️⃣ Waste, Scrap & Yield Management

What they want

- Capture:

- Scrap

- Process loss

- Rework

- Compare expected vs actual yield

Business impact

- Reveals hidden losses

- Improves margin over time

- Encourages continuous improvement

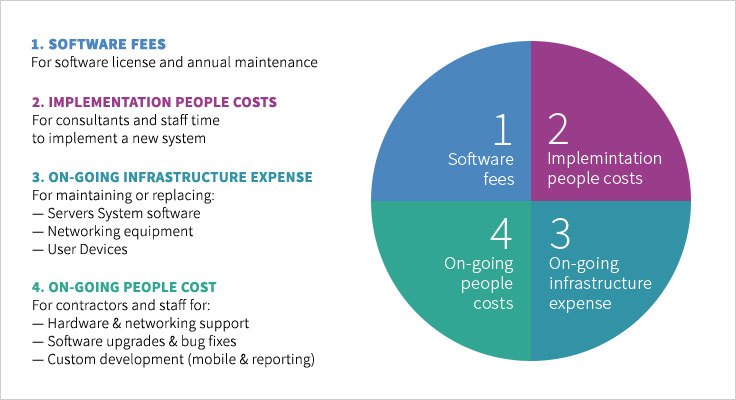

8️⃣ Financial Integration (CEO-Level Expectation)

What they want

- Automatic posting to:

- Inventory valuation

- COGS

- Production overheads

- Real-time impact on:

- Profit & Loss

- Balance Sheet

Key expectation

“Production should automatically reflect in my accounts — no manual journals.”

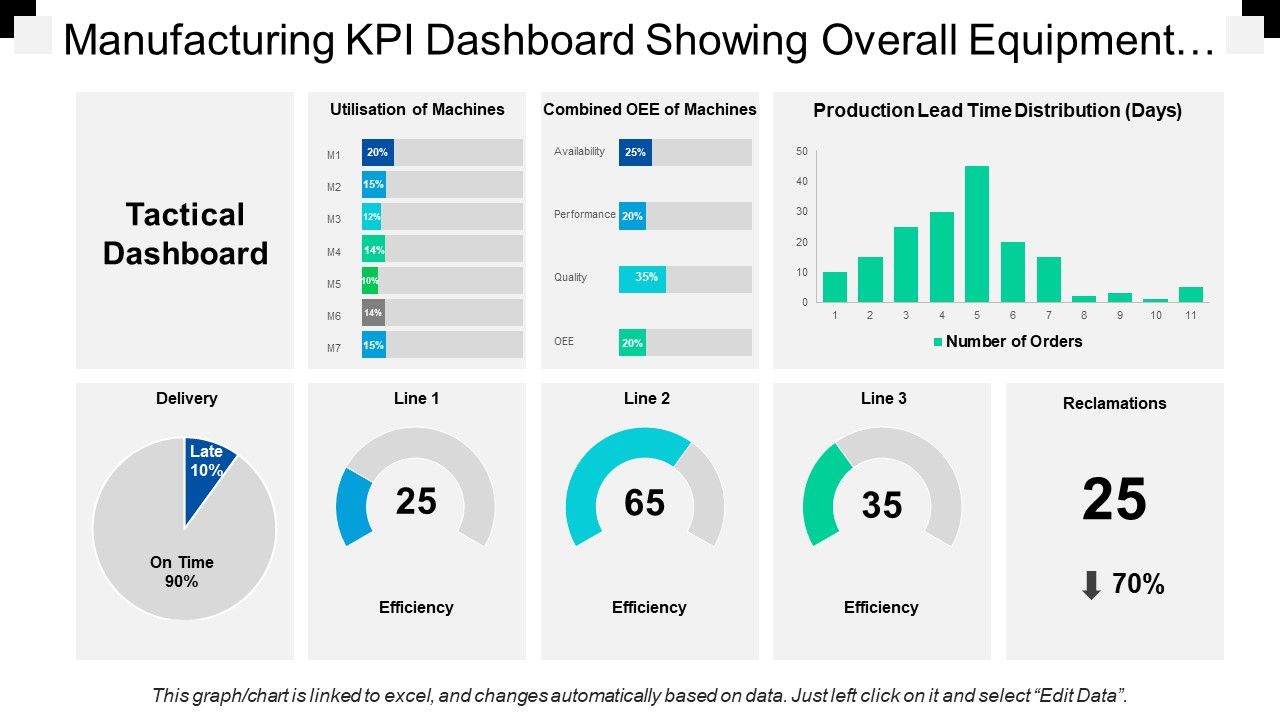

9️⃣ Reporting, Dashboards & Decision Support

What they want to see

- Cost per unit (trend)

- Production efficiency

- Material variance

- On-time delivery rate

- Profitability by product

Used by

- Owners

- Operations managers

- Finance teams

10️⃣ Scalability & Process Discipline

What growing companies expect

- Same system works for:

- 1 factory → multiple plants

- 10 SKUs → 1,000 SKUs

- Enforced processes (less dependency on individuals)

🔑 In Simple Terms

Manufacturers don’t buy ERP manufacturing modules just to record production.

They buy it to:

✔ Control cost

✔ Predict demand

✔ Reduce waste

✔ Improve efficiency

✔ Protect margins

✔ Scale confidently

🎯 ERPNext-Specific Insight (from real projects like yours)

Based on your ERPNext manufacturing work in Ghana:

- Most manufacturers initially want inventory & costing

- Later they demand planning, WIP visibility, and dashboards

- Owners eventually ask:

“Show me where the money is leaking in production.”

More articles on Erpnext